If you are installing a new HVAC unit or you are recovering a system, pulling a system into a vacuum is a basic process. When a vacuum pump is installed correctly your system can be free of moisture, non-condensable gases and contaminants that can destroy your unit or lower its effectiveness.

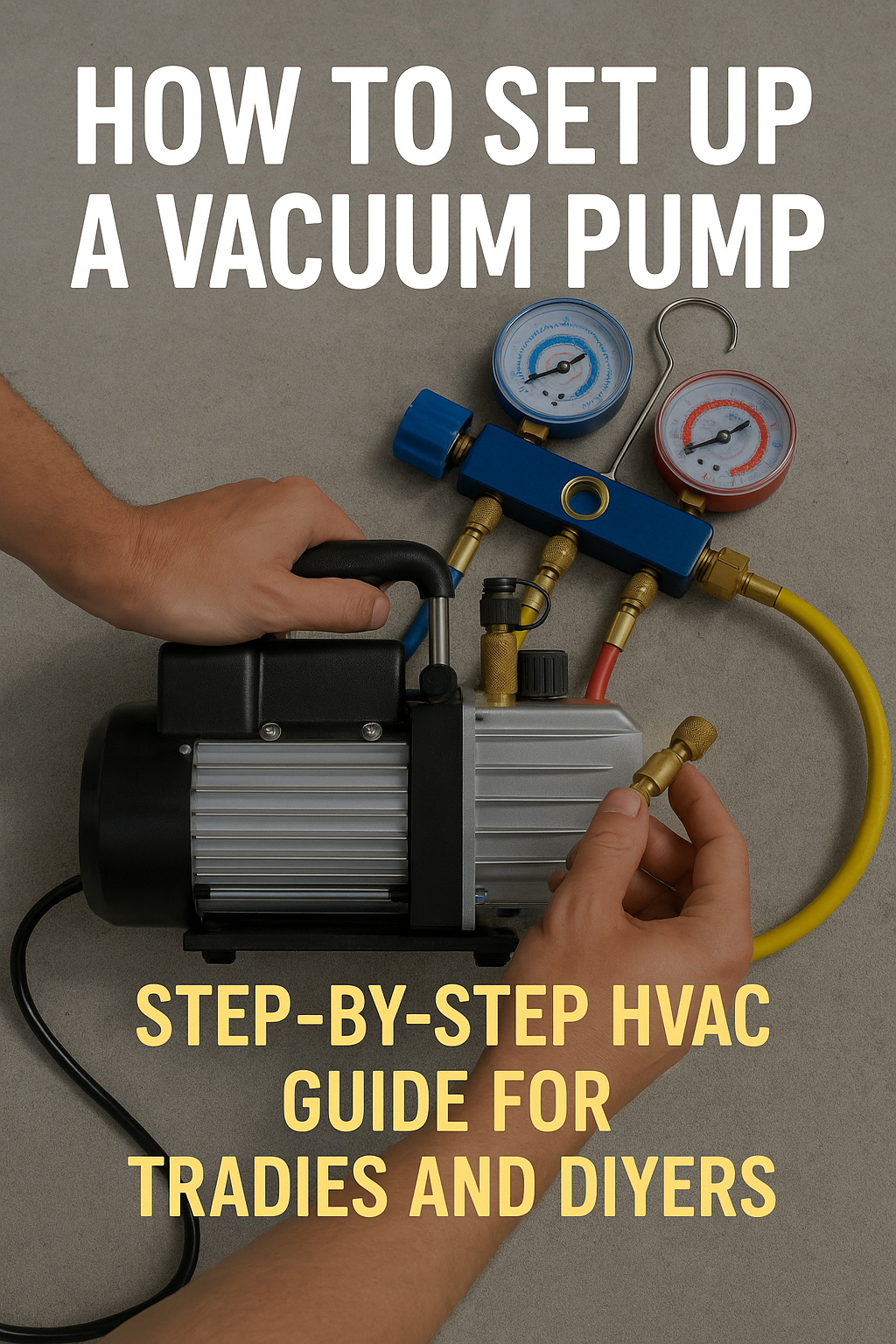

In the following guide, we'll give you an easy step-by-step guide on how to install a vacuum pump including:

- What you’ll need Required tools and fittings

- Key safety tips

- How to avoid common mistakes

- Professional and Practical Advice from My Grandparents’ Times

Let’s get straight into it.

Why You Need a Vacuum Pump for HVAC Work

A vacuum pump is required in HVAC to remove air and moisture and to ensure system cleanliness and integrity, and because it removes water, air and gas from the system before filling, the risk of a chiller experiencing a failure is reduced.

Without adequate evacuation, line moisture may:

- Freeze and cause blockages

- Corrode internal components

- Combined with refrigerants to produce acids.

That’s why learning how to install a vacuum pump is more than just technical, it’s best practice for the life of the system.

🧰 Tools and Supplies You’ll Need

As long as we’re not quite ready to take the plunge, let’s start building our supply list for the essentials:

✔️ Vacuum Pump

For residential or commercial HVAC work, high quality oil sealed rotary vane pump or dual-stage vacuum pump which draws at least 5 CFM.

👉 Popular model: Promax Minimax E High-Pressure Recovery Unit

✔️Manifold Gauge Set (with vacuum rated hoses)

- 3 or 4 hoses (red,blue,yellow,black)

- Fittings with minimal loos (to avoid loss of refrigerant)

- High pressure rating for HVAC application

✔️ Micron Gauge / Vacuum-Gauge

Determines how deep your vacuum is — not your pump gauge alone!

✔️ Valve Core Removal Tool

Optional but recommended to extract Schrader cores during evacuation for quick pull-down.

✔️ Safety Gear

- Safety glasses

- Gloves

- Clear workspace

⚙️ Step by step: How to install a vacuum pump

Now, the news you were waiting for—here’s how you are going to set up your vacuum pump like a boss.

Step 1: Check and Prepare Your Gear

Monitor the oil level of the vacuum pump.

If the oil appears milky or is dark in color, discard the oil and replace it with new vacuum pump oil. Dirty oil can degrade your machines performances and cause wear.

Inspect hoses and gauges.

Check for any holes in the hoses and that all the gaskets are clean and intact.

Step 2: Hooking the Manifold Gauge to the System

- Connect the blue hose to the low pressure port on the HVAC unit.

- Attach the red hose to the high pressure port (optional with basic system, common with 4 port installs).

- Attach the yellow (or black, if the yellow is not available) hose to the suction pump.

🛠️ Pro Tip: A short, large-diameter hose flows better and evacuates faster. Never use long, thin taper vacuum hoses that cut down on vacuum lifting.

Step 3: Attaching the Micron Gauge Open the storage area of your micron gauge and attach it to the end of the hose.

Connect your micron-gauge to as remote from the vacuum pump as is feasible (regularly the service port on the system). This provides an accurate reading of internal system pressure, rather than what’s at the pump, and a warning that something’s wrong.

If you have to, use a T-fitting or core removal tool with a built-in port.

Step 4: Pull Your Schrader Valve Cores (If Desired and Recommended)

Remove the Schrader cores from the service valves using a valve core removal tool. This dramatically speeds up the vacuum.

⚠️ Use caution: Schrader cores are pressurized when removed after charging. Only ever do this step before you pull a vacuum.

Step 5: Start the Vacuum Pump

- Connect and power on the vacuum pump.

- Open the low-side (and high-side, if your system uses one) valves on the service manifold.

- Let the pump run to below 500 microns.

🧪 Aim for:

- 500 microns or so for rudimentary decontamination

- (deep empt) 250-350 microns (preferre d)

- Under 100 microns for critical systems (lab-grade)

Run it longer if not or if you need repeat the process.

Step 6: Check the Micron Gauge

Allow the vacuum to hold for 10–15 minutes after the system has dropped to the micron level in which you want. This “decay test” is what would verify that there are no leaks or moisture.

"Hypertension can occur very fast:

- Your system may be leaking or your hoses might be to blame.

- Moisture may still be spewing off.

- A valve could be cracked open, or the core wasn't removed properly.

Run it longer if not or if you need repeat the process.

Step 7: Close the Vales and Turn the Pump Off

Once the system has succeeded the superposition of decay:

- First close the valves of the manifolds to isolate the vacuum.

- Then turn off the pump.

- Leave the micron gauge attached and watch for any pressure increment.

Step 8: Install Schrader Valve Cores Reinsert the cores inside the valises with a Torx attachment.

if you had to take out the cores, put them back in carefully with your valve core tool.

Just be sure to snug them without over-tightening.

9:Charge System (Punch it to charge)

Now that everything has been replaced or repaired, you’re ready to charge the system and make it operational again.

Remember to:

- Follow good refrigerant handling practices

- Comply with local Australian gas charging and gas disposal regulations

🔍 Common Mistakes to Avoid

❌ Not Using a Micron Gauge

Pressure gauges are not accurate in vacuum levels. to know when moisture is actually gone, you need a micron gauge.

❌ Reusing Old Vacuum Pump Oil

Vacuum oil absorbs moisture. Fill with clean oil after each use for best performance.

❌ Leaky Connections

Use Nylog sealant or appropriate gaskets to prevent leaks between fittings.

❌ Rushing the Process

Run the vacuum as long as necessary. System size and ambient conditions dependent - 30-60 minutes.

🛒 Top Vacuum Pump Accessories for Faster Setup

| Accessory | Purpose | Link |

|---|---|---|

| Valve Core Removal Tool | Faster evacuation by removing flow restriction | View Product |

| Vacuum-Rated Hoses | Ensures no collapse under vacuum | Shop Now |

| Micron Gauge | Accurate measurement of vacuum depth | Explore Micron Gauges |

| Oil Sight Glass Kit | Easily monitor vacuum pump oil levels | Contact HVAC Shop for availability |

🧠 Real Tradie Story: Josh from Melbourne

“Before I learned how to set up a vacuum pump the right way, I always had callbacks—no cooling, noisy compressors, all sorts of dramas. Turns out I was skipping the micron gauge and using a dodgy old hose set. Once I upgraded to a proper pump setup and started hitting 250 microns, all that disappeared. It’s now a non-negotiable part of every install I do.”

🛠️ Vacuum Pump Care For Long Life

- Change oil after each use

- Keep in a dry, clean place

- Plug inlet and outlet ports when not in use

- Clean inlet filter regularly

- Do not over fill the oil filler reservoir

❓ FAQs – How to Install a Vacuum Pump

Q: Can I skip vacuum if system is new and sealed?

No. Even new systems contain air and moisture from factory handling. Always turn off power before charging or installing.

Q: How long do I need to run the vacuum?

Residential System – 30 minutes at the lowest. Use any larger system (or slightly damp weather) will result in a 1–2 hour draw.

Q: Can I substitute the vacuum pump gauge for the micron gauge?

Not recommended. [Pump gauges are not accurate in deep vacuum]

Q: Can I vacuum with the manifold gauge?

Yes — but with large-diameter hoses, no Schrader cores, and as few restrictions as possible.

🔚 Final Thoughts: Mastering the Vacuum = Mastering the System

Learning the proper way to connect a vacuum pump, and operating it is one of the few skills you’ll learn in HVAC school – it’s just that important. Whether you’re an industry professional or an individual ready to tackle that home improvement project, fine-tuning your vacuum setup will provide you with:

- System longevity

- Peak efficiency

- Fewer breakdowns

- Lower energy bills

Invest in quality equipment, and take your time following the steps outlined above to ensure each job is done correctly the first time.

✅ Shop Pro-Grade Vacuum Pumps & Tools at HVAC Shop Australia

Looking for trusted gear? Check out:

We deliver Australia-wide and back all our products with local support and expert advice.