HVAC Shop Valve

83 products

Showing 1 - 24 of 83 products

HVAC Valves, Manifolds & C&D Valve Tools

When you’re opening, isolating or charging a system, the valves and manifolds you use are the only thing between a clean, tight job and a callback. This collection brings together C&D valve tools, Imperial and Mastercool manifolds, piercing valves, ball valves, non-return valves, check valves and valve-core tools — all curated for Australian HVAC-R work.

Whether you’re commissioning new R32 split systems, servicing R410A package units or chasing a stubborn leak on a coolroom, you’ll find the valve hardware and accessories here to keep systems tight, safe and compliant.

What You’ll Find in This Valve Collection

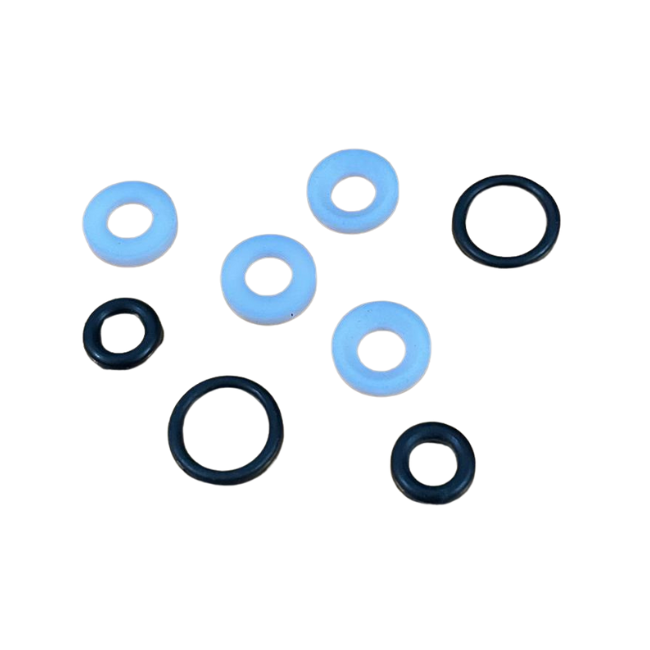

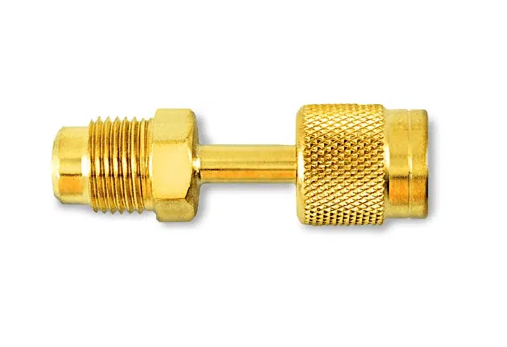

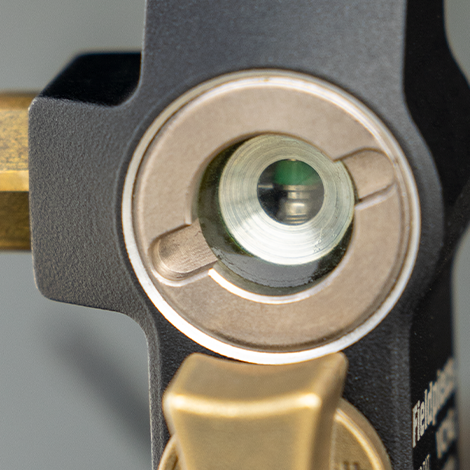

C&D Valve Tools, Cores & Accessories

C&D Valve is a go-to brand for HVAC techs who want reliable access hardware. In this range you’ll typically see:

- Valve core torque drivers & installers – for consistent seating torque on Schrader cores, helping reduce leaks and call-backs.

- Self-piercing line tap valves & bullet piercing valves – for adding temporary access points on suitable copper lines where there’s no factory service port.

- Access fittings, adaptors and core depressors – to connect your hoses, gauges and recovery gear with less restriction and better control.

These tools are built for daily service work on refrigeration and air conditioning systems, and are designed to integrate with common manifolds, hoses and recovery setups.

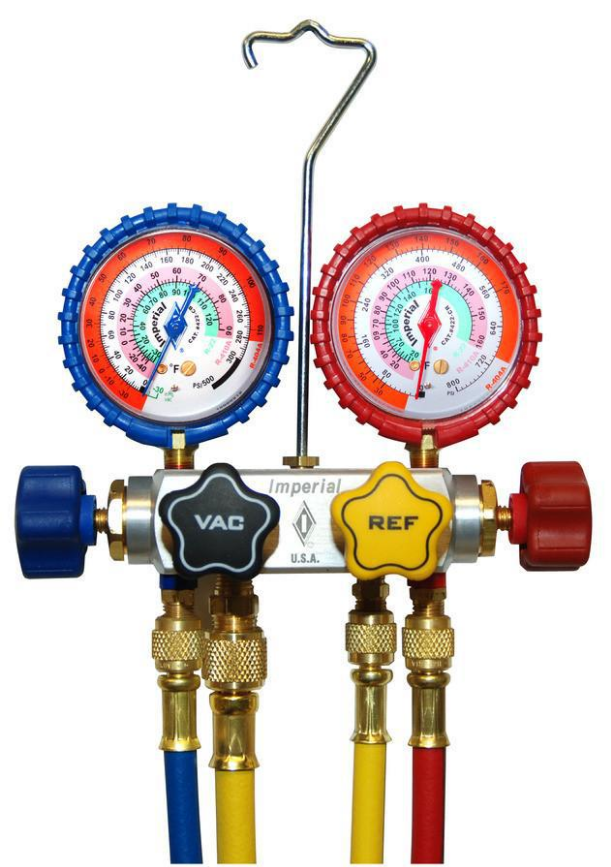

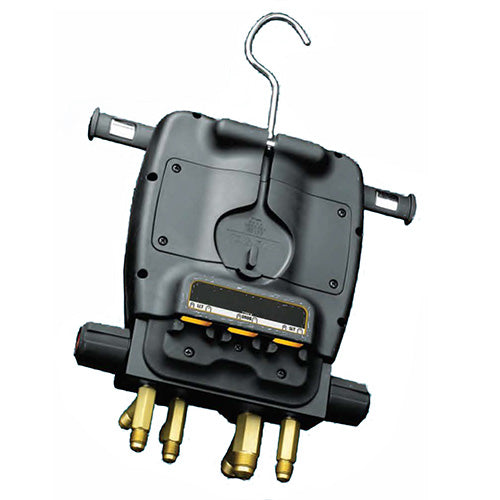

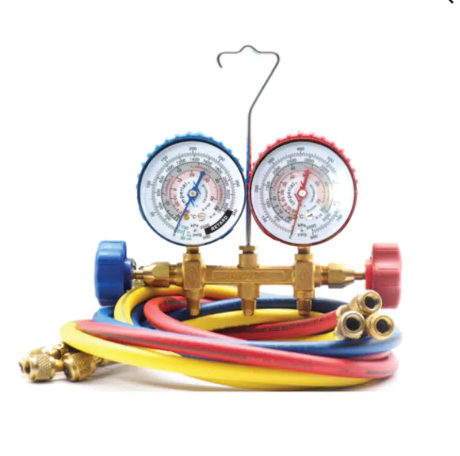

2-Valve and 4-Valve Manifolds

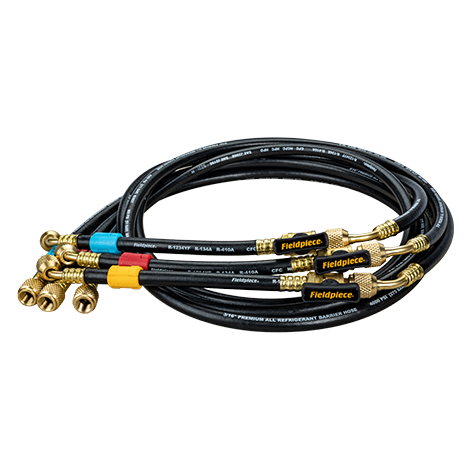

This collection also includes Imperial, Fieldpiece, Yellow Jacket and Hilmor manifolds for refrigerants like R22, R134a, R404A, R410A and R32:

- 2-valve manifolds – compact, tough and ideal for everyday charging, checking superheat/subcool and basic diagnostics.

- 4-valve manifolds – extra ports for vacuum, recovery or simultaneous measurement, saving time on larger systems.

- Digital manifolds with smart charging valves – when paired with digital scales and sensors, they help automate charging and reduce refrigerant waste.

For a full commissioning setup, you can pair these manifolds with our Test & Measurements and Refrigerant Gauges ranges.

Control Valves, Ball Valves & Check Valves

Beyond manifolds and cores, this collection also includes:

- Straight ball valves (e.g. 1/4" SAE) – for positive shut-off and bleed-down on manifolds, hoses and service ports.

- Non-return valves – to prevent backflow and protect pumps and gauges.

- Hydrocell check valves and hose extensions – designed to work with cleaning and wash gear for easier site setups.

Combined with the right hoses and couplings, these components help you build a safer, more controllable rig for evacuation, recovery, leak testing and charging.

How to Choose the Right HVAC Valve or Manifold

1. Match the Refrigerant & Pressure Rating

Always check the markings and manufacturer specs to confirm which refrigerants a manifold or valve is designed for (for example, R32, R410A, R22, R134a, R404A). R32 and many HFCs can run at relatively high pressures, so the valve body, gauges and hoses must be suitably rated.

- Use R32/A2L-rated manifolds, hoses and valves where required.

- Don’t assume an older R22 manifold is suitable for R410A or R32 unless the manufacturer says so.

- When in doubt, refer to the original product documentation and Australian refrigerant codes of practice.

2. Choose 2-Valve vs 4-Valve Manifolds

A 2-valve manifold (one high-side, one low-side) is ideal for regular split-system service, leak checks and small commercial jobs – simple, light and fast to set up.

A 4-valve manifold adds dedicated ports for vacuum pumps and recovery units, so you can evacuate or recover refrigerant without constant hose changes. For VRF, multi-head systems and larger ducted installs, this setup can significantly reduce time on site.

If you’re regularly connecting to a vacuum pump or recovery unit, pairing a 4-valve manifold with core-removal tools and large-bore hoses is a smart way to chase deeper vacuums with less hassle.

3. Match Port Sizes, Threads & Hoses

Most HVAC valves and manifolds in this range use standard SAE flare connections (commonly 1/4", 5/16" or 3/8"). Always:

- Confirm the SAE size and thread against the system or hose you’re connecting to.

- Check compatibility with your existing refrigerant hoses and couplers.

- Avoid unnecessary adaptors that can restrict flow or introduce extra potential leak points.

4. Choose for the Job, Not Just the Hardware

- Service & maintenance – compact 2-valve manifolds, C&D cores, core depressors and basic ball valves cover most day-to-day RAC work.

- Commissioning & changeouts – 4-valve manifolds, valve-core remover/installer tools, large-bore hoses and non-return valves help achieve deep, dry vacuums.

- Cleaning & preventative maintenance – check valves and ball valves can integrate with cleaning and coil-wash setups for safer, more controlled coil cleaning and flushing workflows.

Safety, Licensing & Compliance in Australia

Any time you’re opening a system, swapping valve cores or connecting manifolds, you’re working on refrigeration and air conditioning (RAC) equipment. Under Australian law, handling regulated refrigerants generally requires a valid Refrigerant Handling Licence (RHL).

- You must hold an ARCtick Refrigerant Handling Licence to do anything with a regulated refrigerant that could cause leakage.

- This includes installing, servicing, maintaining or decommissioning RAC equipment and components.

- Licences are issued by the Australian Refrigeration Council (ARC) on behalf of the Australian Government.

Many modern systems use lower-flammability A2L refrigerants such as R32, which add further safety considerations around ignition sources, ventilation and leak management. Always follow manufacturer instructions, Australian codes of practice and any site-specific safety procedures.

If you’re not licensed, you can still purchase tools and accessories from HVAC Shop, but any work involving refrigerant should be carried out by a licensed RAC technician in line with Australian regulations.

Who This Valve Range Is For

- HVAC & refrigeration technicians – daily-use manifolds, valve core tools, piercing valves and check valves for service and commissioning.

- Apprentices & junior techs – building a trade-ready kit with proven brands like C&D, Imperial, Mastercool and Fieldpiece.

- Maintenance & facility teams – looking after commercial plant, coolrooms or VRF systems where reliable isolation valves are essential.

- DIY-curious owners (limited use) – some accessories support cleaning and non-refrigerant tasks, but any refrigerant work must be done by a licensed tech.

If you’re unsure which manifold or valve hardware suits your workload, reach out via our Contact HVACShop page for personalised support.

Valve & Manifold FAQ

What’s the difference between a 2-valve and 4-valve manifold?

A 2-valve manifold has one high-side and one low-side valve and is ideal for everyday service work: checking pressures, superheat and subcool, and basic charge adjustments. A 4-valve manifold adds extra ports for vacuum and recovery connections, so you can evacuate or recover refrigerant without constantly swapping hoses, which saves time and reduces the risk of pulling air into the system.

Are C&D self-piercing and bullet piercing valves permanent fittings?

In most workflows, piercing valves are treated as temporary access points on suitable copper lines where there’s no factory service port. After recovery, pressure testing and repairs are complete, many technicians will replace the copper section or install a permanent access fitting, in line with manufacturer instructions and Australian refrigerant codes of practice.

Can homeowners or unlicensed users work with these valves?

Homeowners and other trades can purchase tools, manifolds and valves, but handling regulated refrigerants or performing work that could cause a leak generally requires a valid Refrigerant Handling Licence in Australia. If you’re not licensed, leave any refrigerant-circuit work to a licensed RAC technician.

How do I know if a manifold is compatible with R32 or A2L refrigerants?

Check the manifold’s refrigerant markings, pressure ratings and manufacturer documentation. Look for explicit R32 or A2L compatibility, and make sure your hoses, recovery units and vacuum pumps are also rated accordingly. Always follow the relevant Australian safety standards for flammable refrigerants.

How often should valve cores and access fittings be replaced?

There’s no fixed schedule, but it’s good practice to inspect valve cores during routine service visits and replace any that leak, are damaged or slow to seal. Using quality cores and proper core-torque tools helps reduce micro-leaks. Always leak-test after replacing cores or fittings.

How do these valves and manifolds support energy efficiency?

Leak-free valves and correctly charged systems help maintain design pressures and temperatures, reduce refrigerant loss and support proper evacuation and moisture removal. Combined with regular coil and filter cleaning, that leads to better performance, fewer call-backs and lower running costs over time.

About This Page

Author: HVACShop Content Team

Technical review: Licensed refrigeration & air-conditioning technician (ARCtick)

Business entity: Stella Aquatics Pty Ltd trading as HVACShop.com.au – ABN 98 351 143 900

Contact: Phone 0412 333 115, Email hvacshop.com.au@gmail.com (Mon–Fri, 9:00am–5:00pm AEST)

Disclaimer: This page is general information for HVAC professionals and does not replace manufacturer documentation, Australian standards or professional advice. Refrigerant handling work must only be carried out by appropriately licensed technicians.

Last updated: 2025-12-17T00:00:00+11:00