Hoses & Couplings

38 products

Showing 1 - 24 of 38 products

Hoses & Couplings for Refrigerant Charging, Evacuation & AC Service

This range brings together refrigerant charging hoses, evacuation hoses, quick-connect couplers and automotive AC fittings that Aussie HVAC and refrigeration techs actually use on site. Whether you are charging R32 minisplits, recovering R410A from a rooftop system, or servicing automotive R134a, these hoses & couplings are built for reliable sealing, high pressure and everyday field abuse.

You will find proven brands like Imperial, Mastercool, Robinair, All Controls and Javac in one place, backed by fast Australian shipping and friendly support from the HVAC Shop team.

What You’ll Find in This Hoses & Couplings Range

Instead of guessing in a generic plumbing aisle, this collection is curated for HVAC/R work. Typical jobs include commissioning new split systems, deep evacuation on larger plant, leak testing, recovery, and automotive AC service. In this category you will find:

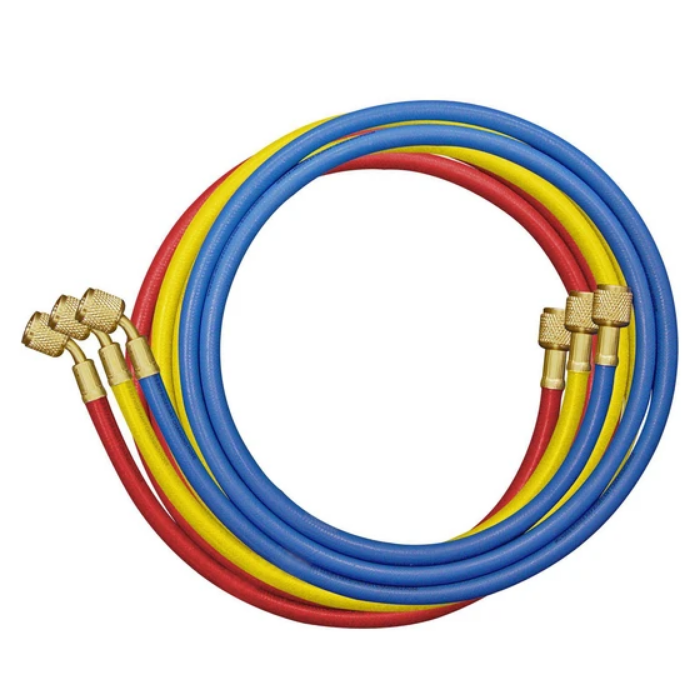

- Refrigerant charging hose sets – standard 3-hose sets in 1/4" and 5/16" SAE for connection between your manifold gauge set and the system, with colour-coded red/yellow/blue hoses for easy identification.

- High-pressure PolarShield® and similar hose sets – for modern high-pressure refrigerants such as R410A and R32, with working and burst pressure ratings that suit today’s systems (always confirm the exact rating in the product spec before use).

- Wide-bore evacuation hoses – 3/8" hoses designed to maintain conductance during deep vacuum, especially when paired with a quality vacuum pump and core removal tools to remove restrictions.

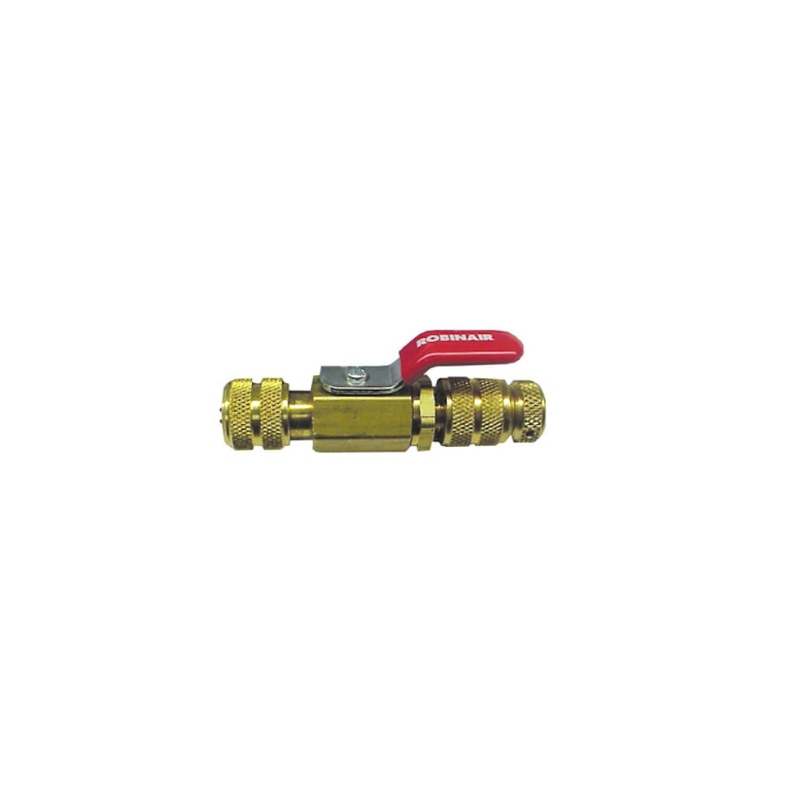

- Kwik-couplers and service couplers – straight and elbow couplers in 1/4" and 5/16" sizes for R410A, R32, R22, R404A and other common refrigerants, including options with manual or automatic shut-off.

- Valve core remover tools and adapters – to safely remove cores and convert between 1/4", 5/16" and 3/8" ports without creating choke points in your hose run.

- Automotive AC couplers – high and low side R134a couplers and kits built for workshop use on passenger vehicles and light commercial fleets.

- Copper and CO2 fittings – specialised elbows and couplings rated for high pressure refrigerants including CO2 (R744); always follow manufacturer limits and system design.

To drill into more specific sub-ranges, you can also browse:

- Refrigerant Hoses – focused on charging and service hoses in different lengths and diameters.

- Couplings – pipe and hose couplings, elbows and fittings for refrigeration installs and repairs.

- Automotive Coupler – dedicated to automotive AC couplers and quick-connect fittings.

How to Choose the Right Hose & Coupler

The best hose or coupling for a job usually comes down to three things: size, refrigerant compatibility and application. Use the checklist below as a quick guide before you hit "add to cart".

1. Hose Size, Length & Flow

- 1/4" SAE hoses – the everyday workhorse size for many manifolds and vacuum pumps. Ideal for general service work and smaller systems.

- 5/16" SAE hoses and couplers – common on modern split system service ports, especially for R410A and R32. Make sure you have matching 5/16" couplers if you service a lot of minisplits.

- 3/8" SAE evacuation hoses – wide-bore hoses for faster evacuation and deeper vacuum on larger systems, where restriction in the hose run can slow you down.

- Short vs long hoses – short hoses are ideal for evacuation straight off the pump and core tools, while longer hose sets are handy when you need to stand clear of fans, hot discharge lines or busy plant rooms.

2. Refrigerant & Oil Compatibility

Not every hose is rated for every refrigerant. When you are working with high-pressure or flammable refrigerants such as R410A, R32 or CO2, always double-check:

- The hose’s working pressure and burst pressure rating against the system’s design pressure.

- The list of approved refrigerants in the product description (for example, many modern charging hoses are specifically rated for R410A/R32 as well as legacy HFCs and HFOs).

- Oil compatibility – especially when switching between mineral oil systems and POE/PAG oil systems; follow manufacturer recommendations.

If you are working on flammable or mildly flammable refrigerants (A2L or A3), choose hoses and couplers clearly marked as suitable, and follow all relevant Australian standards and site safety procedures.

3. Application: Charging, Evacuation, Recovery or Automotive

- Charging hose sets – standard 3-hose sets between the manifold and the system. Look for anti-blowback features, swivel ends, and shut-off valves where appropriate.

- Evacuation hoses – wide-bore, as short as practical, and connected via core tools to minimise restrictions so your vacuum pump can pull down quickly and cleanly.

- Recovery hoses & couplers – check the rating against your recovery unit’s maximum operating pressure; high-pressure and CO2-rated parts are critical when dealing with transcritical or high-pressure circuits.

- Automotive AC couplers – R134a or R1234yf-specific high and low side quick-connects designed for automotive service ports rather than stationary plant.

Safe, Standards-Aligned Use in Australia

Refrigerant handling in Australia is regulated. Hoses and couplings are not just convenience items – they play a key role in preventing leaks, protecting technicians and avoiding illegal discharge of refrigerant to atmosphere. These products are intended for use by licensed HVAC/R professionals.

ARCtick Licensing & Legal Reminder

Connecting, disconnecting, charging and recovering refrigerant is licensed work. In Australia, you must hold an appropriate ARCtick Refrigerant Handling Licence to carry out this work, and building owners or homeowners should always engage licensed contractors. Hoses and couplers should never be used by unlicensed DIYers for refrigerant work.

When in doubt, verify the technician’s licence via the official ARCtick resources, and always follow the latest refrigerant handling codes of practice and manufacturer instructions.

Flammable Refrigerants (R32, R290, R600a and Others)

Modern systems increasingly use flammable or mildly flammable refrigerants such as R32, R290 and R600a. When working on these systems:

- Use hoses, couplers and tools that are clearly rated for the refrigerant in question.

- Keep ignition sources away from the work area and maintain good ventilation.

- Avoid creating sparks through impact, grinding, or poor electrical connections near the system.

- Follow all site-specific Safe Work Method Statements (SWMS) and workplace health and safety requirements.

Quick Pre-Use Checklist for Hoses & Couplers

- Visually check hoses for cracking, kinking, blistering or damaged outer jackets.

- Inspect coupler O-rings and seals for flattening, cuts or contamination – replace if in doubt.

- Confirm thread type and size (1/4", 5/16", 3/8" SAE, etc.) before connecting to avoid cross-threading.

- Pressure test with dry nitrogen where appropriate before introducing refrigerant.

- Use suitable leak detection methods after connections have been made.

Regular inspection and replacement of hoses and couplings helps maintain system efficiency, reduces call-backs and supports compliance with Australian refrigerant handling requirements.

Build a Complete Charging, Evacuation & Recovery Kit

Hoses and couplings are only one part of the picture. To get faster vacuums, cleaner recoveries and reliable system charging, pair this range with purpose-built tools across HVAC Shop:

- Manifold, AC & Refrigerant Gauges – match your hose sets with 2-valve or 4-valve manifolds and digital gauges for accurate diagnostics.

- Vacuum Pumps – deep vacuum pumps that deliver consistent performance when paired with short, wide-bore evacuation hoses.

- Recovery Units – for safe and compliant refrigerant recovery, especially on larger systems and high-pressure gases.

- Recovery & Evacuation Equipment – build a complete kit with hoses, scales, vacuum gauges and accessories.

For deeper how-to guidance and comparison tips on hose couplings, vacuum pumps and recovery gear, explore:

Hoses & Couplings FAQs

Which hose size should I use for R32 and R410A split systems?

Most modern split systems use 5/16" SAE service ports, so you will typically pair a 5/16" coupler with 1/4" hose sets via an adapter, or use hose sets supplied with 5/16" ends. Always confirm the service port size on the nameplate or in the service manual and match your couplers and hoses accordingly.

Can I use these hoses with flammable refrigerants like R32, R290 or R600a?

Some hoses and couplers in this collection are rated for use with flammable or mildly flammable refrigerants, others are not. Always check the approved refrigerant list and pressure rating in the product description. If a product is not clearly marked as suitable for a specific refrigerant, treat it as not approved and choose a rated alternative.

Do I need an ARCtick licence to buy or use hoses & couplings?

You do not need a licence to purchase hoses and couplings, but you do need an appropriate ARCtick Refrigerant Handling Licence to carry out any work that could release refrigerant (charging, recovery, connecting or disconnecting from live systems). These tools are intended for use by licensed technicians.

What is the difference between charging hoses and evacuation hoses?

Charging hoses are typically 1/4" hoses used between your manifold and the system for charging and diagnostics. Evacuation hoses are usually wider-bore (often 3/8"), used between the system (via core tools) and the vacuum pump to maximise flow and achieve deeper vacuums in less time. Many techs use short, dedicated evacuation hoses to keep restrictions to a minimum.

How often should I replace my refrigerant hoses and couplers?

There is no single interval that suits every technician. As a rule of thumb, replace hoses and couplers whenever you see signs of wear (cracks, blisters, damaged crimps, leaking O-rings) or after severe contamination or overheating events. Regular leak checks and visual inspections will usually tell you when a hose or coupler should be retired from service.

Are these hoses suitable for automotive air conditioning work?

Yes, many hose sets and couplers in this collection are suitable for automotive R134a or R1234yf systems when used with the correct automotive AC couplers and rated equipment. Check each product’s refrigerant compatibility and pair them with items from the Automotive Coupler collection for workshop use.

How can I minimise leaks at hose couplings under vacuum?

Keep threads clean, replace worn O-rings, avoid over-tightening, and standardise your hose run sizes (for example, 1/4" or 3/8" from pump to system with minimal adapters). Using quality core remover tools, wide-bore evacuation hoses and rated couplers will reduce restrictions and leak points, while regular leak checks catch problems early.

Author: HVACShop.com.au – HVAC Tools & Trade Support Team

Technical review: Internal review by ARC-licensed refrigeration & air conditioning technician (Australia)

Business details:

HVACShop.com.au

ABN 98 351 143 900

Email: hvacshop.com.au@gmail.com

Phone: 0412 333 115 (Mon–Fri, 9:00am–5:00pm AEST)

Last updated: 2025-12-05 (AEST)